Cornell’s Shape-Shifting Micro-Robots: A Leap into the Future of Robotics

Revolutionizing Microscale Robotics

In recent years, microscale robotics has seen breathtaking advancements that challenge the limits of what can be achieved at such a small scale. From promising medical innovations to groundbreaking environmental monitoring, researchers are spearheading an exciting era of transformation. One remarkable contribution in this field comes from Cornell University, where a dedicated team has engineered microscale robots capable of changing shape on command, a development that could reshape the landscape of robotics.

Meet the Innovators Behind the Breakthrough

The visionary behind this project is Professor Itai Cohen, a prominent figure in Cornell’s Department of Physics. Under his guidance, a team has crafted robots measuring less than a millimeter in size. This pioneering development allows these robots to transition from flat two-dimensional structures to intricate three-dimensional forms, an advance meticulously detailed in their paper published in Nature Materials.

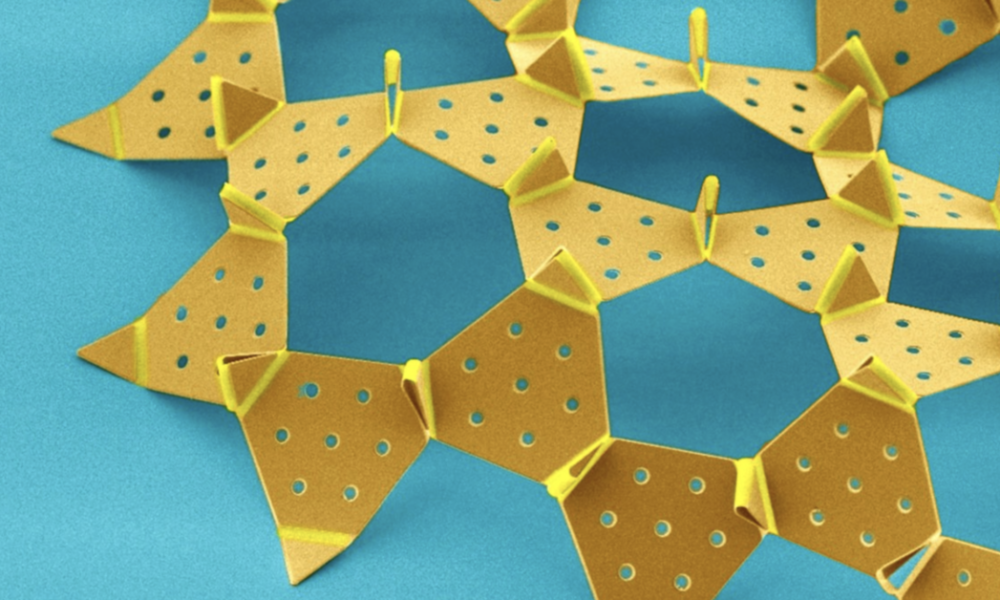

The Art of Kirigami in Engineering

At the core of this technological leap lies the application of kirigami techniques, which are rooted in the traditional Japanese art of paper cutting and folding. Unlike typical origami that focuses solely on folding, kirigami incorporates strategic cuts, offering engineers the ability to create structures that can morph into various shapes predictably and precisely.

A Design Breakthrough: The Metasheet Robot

The researchers have dubbed their creation the “metasheet robot.” This innovative term references metamaterials, which are engineered to possess unique properties not found in nature. The metasheet consists of an array of components that synchronize to enable remarkable mechanical behaviors.

Versatility at Its Best

This groundbreaking design enables the metasheet robot to modify its coverage area, changing its dimensions locally by up to 40%. Such flexibility allows these minuscule robots to interact with their environments in ways that were previously unimaginable at this scale.

Delving into the Technical Specifications

Constructed through hexagonal tiling, the microscale robots comprise approximately 100 silicon dioxide panels, each interconnected by over 200 actuating hinges—remarkably thin at just 10 nanometers. This intricate composition forms the backbone of the robots’ ability to change shapes seamlessly.

Electrochemical Activation: The Power Behind Movement

The mechanism of transformation in these robots hinges on electrochemical activation. When an external electrical current is introduced, it prompts the actuating hinges to create dynamic mountain and valley folds. This activation enables the panels to extend and spin, thus facilitating shape transformation.

Controlled Versatility in Motion

By strategically activating different hinges, the robots possess the capability to take on varying configurations. This allows them to wrap around objects or revert to a flat sheet as needed. Their ability to crawl and shift shape in response to electric stimuli marks a significant evolution in microscale robotics.

Promising Applications on the Horizon

The implications of these shape-shifting robots are vast and varied. In the medical field, they hold the potential to revolutionize minimally invasive surgeries. Their nimbleness and adaptability could make them vital for targeted drug delivery systems or intricate microsurgery operations.

Environmental Monitoring Reimagined

In environmental science, these robots could serve as essential tools for monitoring ecosystems and pollutants at the microscale. Their diminutive size and dynamic adaptability allow them to explore and engage with otherwise challenging environments.

A New Era for Materials Science

In the domains of materials science and manufacturing, these robots could act as fundamental components for reconfigurable micromachines. This innovation could pave the way for the creation of smart, adaptive materials capable of altering their properties on demand, unlocking new frontiers in various industries including aerospace engineering and innovative textile designs.

Looking Ahead: Future Research Avenues

The research team at Cornell isn’t resting on their laurels; they’re paving the way for forthcoming breakthroughs. One potential direction involves developing “elastronic” materials—an integration of flexible mechanical structures with responsive electronic controls.

Envisioning Intelligent Matter

Professor Cohen foresees these advanced materials reacting intelligently to external stimuli. Imagine materials that can swiftly adapt or even move away from an applied force—concepts that push the limits of what is currently feasible.

Energy Autonomy: A Game Changer

Future developments could also focus on enhancing the robots’ capability to harvest energy from their surroundings. By embedding light-sensitive electronics in their structural components, the goal is to create robots that function autonomously over extended periods, further revolutionizing their practical applications.

Navigating Challenges on the Path Forward

Despite the exciting prospects that lie ahead, numerous challenges remain. A primary concern is the difficulty in mass-producing these intricate devices while ensuring reliability and precision. The sophisticated architecture of these robots must be meticulously managed to ensure widespread applicability.

Control Complications: Bridging Gaps

Moreover, controlling these robots in real-world scenarios presents formidable challenges. Current research relies on external wired connections, but transitioning to a system with wireless control and power generation remains a significant technological hurdle.

Ethical Considerations in Medical Applications

Ethical questions loom large, especially considering potential medical applications. Utilizing microscale robots inside the human body raises crucial concerns about safety, long-term effects, and patient consent—issues that the field will need to address diligently.

Conclusion: A New Paradigm for Robotics

The creation of shape-shifting microscale robots at Cornell University signifies a monumental advancement in the realm of robotics and materials science. Through innovative applications of kirigami principles, researchers have unlocked a spectrum of possibilities—from groundbreaking medical techniques to enhanced environmental monitoring. Though hurdles in manufacturing, control, and ethical considerations still confront the researchers, they are laying the foundation for future innovations such as elastronic materials. This evolving technology stands to transform not just the field of robotics but a myriad of industries, attesting to the profound impact of advancements at the microscale level on our scientific and societal landscapes.