As Henry Ford once said, “Coming together is a beginning; keeping together is progress; working together is success.” This timeless wisdom resonates deeply in today’s rapidly evolving industrial landscape. Factories are no longer just about machinery; they are becoming hubs of intelligent technology, driving efficiency and innovation.

The integration of advanced systems is transforming traditional operations into flexible, intelligent ecosystems. These changes enable factories to offer more customized and sustainable services, while also enhancing data flow across operational boundaries1. This shift is not just about adopting new tools; it’s about reimagining how factories operate in the future.

Real-time analytics and localized data processing are at the heart of this transformation. By bringing computational power closer to devices, factories can make faster decisions and avoid disruptions1. This approach not only improves efficiency but also reduces operational costs, making factories more competitive globally.

Key Takeaways

- Intelligent technology is reshaping factory operations for greater efficiency.

- Real-time analytics enable faster decision-making and disruption avoidance.

- Localized data processing enhances operational flexibility and sustainability.

- Advanced systems reduce costs and improve global competitiveness.

- Factories are evolving into hubs of innovation and customized services.

Introduction: The Evolution of Manufacturing in the Digital Age

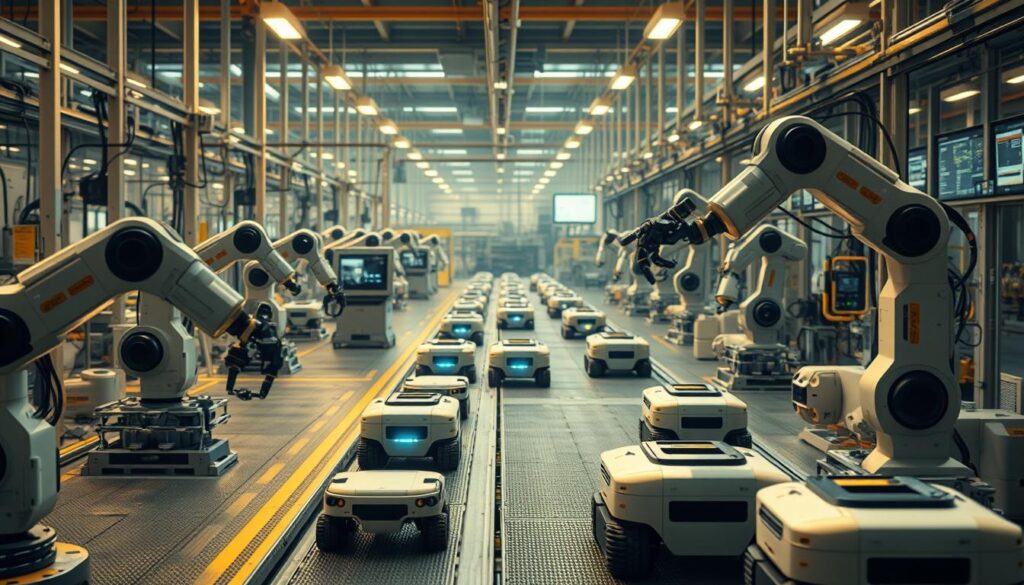

From manual labor to smart systems, the journey of manufacturing has been nothing short of revolutionary. Over the decades, factories have transitioned from relying solely on human effort to embracing advanced technologies that redefine operational efficiency.

The integration of intelligent systems has played a pivotal role in this transformation. Sensors, IoT devices, and data-driven insights have become the backbone of modern operations. These tools enable factories to collect and analyze vast amounts of information, leading to smarter decision-making and improved outcomes2.

Traditional methods, once the standard, are now being replaced by automated processes. This shift has not only increased productivity but also reduced errors and downtime. For instance, predictive maintenance powered by advanced analysis can cut maintenance costs by 5-10% and boost equipment uptime by 10-20%2.

Digital tools have redefined the way factories operate. Real-time data processing and localized intelligence allow for faster responses to challenges. This approach ensures that factories remain competitive in a rapidly changing global landscape3.

Looking ahead, the role of intelligence in manufacturing will only grow. As factories continue to innovate, they will rely more on data-driven strategies to stay ahead. This evolution marks a new era where efficiency, sustainability, and adaptability are at the forefront of every operation.

Understanding Industry 4.0 and Its Impact on Smart Factories

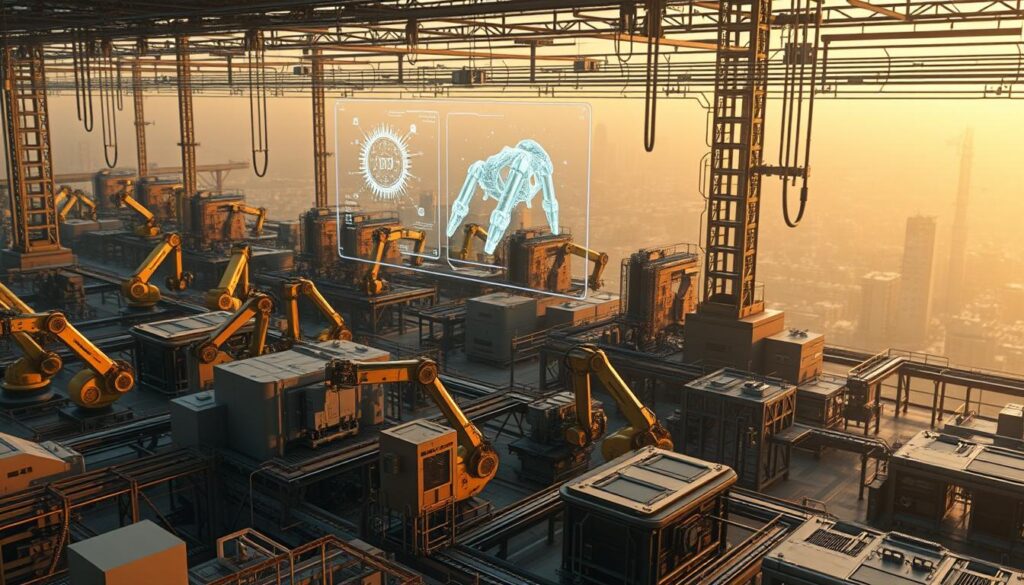

The modern factory is no longer just a place of production; it’s a hub of innovation and connectivity. Industry 4.0 represents the fourth industrial revolution, where advanced technologies merge with traditional processes to create smarter, more efficient operations. This transformation is reshaping the manufacturing landscape, enabling factories to achieve unprecedented levels of productivity and sustainability4.

Key Pillars of Industry 4.0

At its core, Industry 4.0 is built on several key pillars. Connectivity ensures seamless communication between machines, systems, and people. Advanced computing enables real-time data processing, while automation reduces manual intervention and minimizes errors. These elements work together to create a more agile and responsive factory environment5.

Another critical pillar is data analytics. By leveraging real-time insights, factories can optimize resources, predict maintenance needs, and improve overall efficiency. This data-driven approach not only enhances performance but also reduces operational costs significantly4.

The Role of Digital Transformation

Digital transformation is the backbone of Industry 4.0. It involves integrating technologies like IoT, robotics, and cloud computing into factory operations. This integration allows machines to communicate autonomously, making decisions that enhance productivity and reduce downtime5.

For example, smart factories can monitor production processes in real-time, adjusting parameters to maintain optimal performance. This level of control not only boosts efficiency but also ensures consistent product quality. As a result, factories can meet customer demands more effectively while staying competitive in the global market4.

To learn more about how digital transformation is shaping the future of business operations, explore our detailed guide.

The Role of AI Agents in Manufacturing: Driving Industry 4.0

Factories are now leveraging advanced technologies to redefine efficiency and precision. The integration of intelligent systems into daily operations is transforming how tasks are executed. These systems work seamlessly with industrial robots to handle precision tasks, ensuring accuracy and consistency6.

One of the key benefits is the improvement in operational workflows. For example, Hitachi Solutions has successfully implemented intelligent systems to streamline production processes. This has led to a 20% increase in productivity and a 30% reduction in equipment downtime7.

Fujitsu’s approach highlights the synergy between intelligent systems and robots. Their solutions enable real-time adjustments, reducing errors and enhancing output quality. This collaboration ensures that factories can meet demands faster and more efficiently6.

Strategic Importance of Intelligent Systems

These systems are not just tools; they are strategic assets. They drive industry standards forward by enabling smarter decision-making and proactive problem-solving. For instance, predictive maintenance powered by intelligent systems can reduce costs by 10-40% and increase machine uptime by 10-20%8.

As factories continue to adopt these technologies, they set new benchmarks for efficiency and innovation. The result is a more competitive and sustainable industrial landscape, where intelligent systems play a central role in shaping the future.

Edge AI and Real-Time Process Optimization

The future of factory operations lies in real-time adaptability and intelligent solutions. By processing data closer to the source, edge computing minimizes delays and enhances decision-making. This approach not only improves efficiency but also reduces operational costs significantly9.

Reducing Latency and Enhancing Data Security

Edge computing reduces latency by processing data locally, ensuring faster responses. This is critical for real-time process optimization, where delays can lead to inefficiencies. Additionally, keeping data on-site enhances security, reducing the risk of breaches10.

For example, localized data processing can improve operational efficiency by up to 30%. This is achieved by eliminating the need to send data to remote servers, which often causes delays9.

Improving Operational Continuity

Edge computing ensures uninterrupted operations by enabling real-time analysis and adjustments. This is particularly useful in predictive maintenance, where it can reduce equipment downtime by 20-50%9.

By leveraging edge computing, factories can achieve continuous improvements in their processes. This not only boosts productivity but also ensures consistent quality, meeting customer demands more effectively10.

The potential of edge computing extends beyond efficiency. It also supports sustainability by optimizing energy consumption, leading to a 10-15% reduction in energy usage9.

Applications of AI in Predictive Maintenance and Process Automation

The integration of intelligent systems is revolutionizing how factories approach maintenance and automation. By leveraging advanced technologies, factories can anticipate equipment failures, streamline processes, and enhance overall productivity. This shift not only reduces costs but also ensures smoother operations.

Minimizing Unplanned Downtime

Unplanned downtime can be costly and disruptive. Intelligent systems analyze data from equipment to predict potential failures before they occur. For example, predictive maintenance can reduce downtime by up to 50%, ensuring continuous operations11.

Volkswagen uses sensor data to forecast maintenance needs, streamlining operations and minimizing disruptions12. This proactive approach not only saves time but also extends the lifespan of machinery, reducing long-term costs.

Boosting Efficiency and Productivity

Process automation is another key benefit of intelligent systems. By automating repetitive tasks, factories can save time and reduce errors. For instance, Whirlpool uses robotic process automation to enhance accuracy and productivity in manufacturing12.

These systems also optimize resource allocation, leading to reduced waste and more efficient production. Organizations using intelligent technologies have reported a 10% reduction in production expenses11. This improvement in efficiency directly translates to higher output quality and customer satisfaction.

In summary, the application of intelligent systems in maintenance and automation is transforming factory operations. By minimizing downtime and boosting productivity, these technologies are setting new standards for efficiency and innovation.

Intelligent Manufacturing Technologies: From Digital Twins to IoT Integration

The fusion of cutting-edge technologies is reshaping the way factories operate. Emerging tools like digital twins and IoT are empowering smart factories to achieve unprecedented levels of efficiency and flexibility. These innovations bridge the gap between physical and digital ecosystems, enabling real-time monitoring and decision-making13.

Leveraging Cloud and Edge Computing

Cloud and edge computing are at the forefront of this transformation. By combining scalable cloud solutions with localized edge processing, factories can optimize operations and reduce latency. This approach ensures faster data analysis and more responsive systems14.

For example, edge computing allows factories to process data closer to the source, minimizing delays. This is particularly useful for real-time applications like predictive maintenance, where quick responses are critical13. Cloud computing, on the other hand, provides the storage and computational power needed for complex analytics.

Advanced software systems are also playing a key role. These systems integrate seamlessly with robotic equipment, enhancing automation and precision. By leveraging intelligent software, factories can streamline workflows and improve overall productivity14.

Robotic systems are another area of focus. Enhanced by new technology, robots can perform complex tasks with greater accuracy. This not only boosts efficiency but also reduces the risk of errors, ensuring consistent quality13.

In summary, the integration of digital twins, IoT, and advanced computing is driving the future of manufacturing. These technologies enable factories to operate smarter, faster, and more efficiently, setting new standards for the industry.

AI-Powered Supply Chain and Inventory Management

The logistics landscape is undergoing a seismic shift with the integration of advanced technologies. Businesses are now leveraging intelligent solutions to streamline their supply chain operations, ensuring greater efficiency and transparency. This transformation is not just about speed; it’s about making smarter decisions that drive long-term success.

One of the most significant advancements is in inventory management. By using real-time data, companies can optimize stock levels, reducing overstocking and preventing stockouts. This approach not only cuts costs but also ensures that businesses can meet customer demands more effectively15.

Smart Asset Tracking Solutions

Smart asset tracking is revolutionizing how businesses monitor their resources. With real-time visibility, companies can track shipments and manage inventory levels across multiple locations. This level of control minimizes errors and enhances operational efficiency15.

For example, advanced tracking systems can reduce last-mile delivery costs, which account for up to 28% of total shipping expenses16. By adopting these solutions, businesses can achieve significant savings while improving service levels.

Real-Time Analytics for Enhanced Logistics

Real-time analytics are at the heart of modern logistics. These tools provide actionable insights, enabling businesses to make faster, data-driven decisions. For instance, predictive analytics can improve demand forecasting accuracy, allowing for better inventory adjustments16.

Companies that adopt these technologies can achieve up to a 30% increase in operational efficiency16. This not only boosts productivity but also enhances customer satisfaction through timely updates and personalized services.

To learn more about how intelligent systems are transforming supply chain decision-making, explore our detailed guide.

Innovations in Generative AI for Manufacturing Transformation

The integration of generative systems is reshaping how factories innovate and operate. These advanced tools are not just enhancing efficiency but also driving a significant transformation in how tasks are executed. From improving product quality to enabling autonomous decision-making, the impact of these systems is profound17.

Case Studies in Creative Applications

Industry leaders like GE Appliances, Bosch, and ACG Capsules are at the forefront of this innovation. GE Appliances, for instance, has utilized generative systems to optimize production lines, resulting in a 20% increase in efficiency18. Bosch’s creative application of these systems has reduced project timelines from years to just six months, showcasing their potential for rapid transformation18.

ACG Capsules has also demonstrated the power of collaboration between humans and systems. Their generative assistant was adopted by 75% of operators within five weeks, reducing repair times by 30-40%18. These examples highlight how generative systems are driving measurable improvements in service levels and defect reduction.

Advances in Autonomous Decision-Making

One of the most exciting developments is the rise of autonomous decision-making. These systems analyze vast amounts of datum to make real-time adjustments, ensuring optimal performance. For example, PepsiCo’s use of generative systems in Cheetos production has allowed for autonomous supervision of machine settings, enhancing quality control17.

Such advancements are not just about efficiency; they also pave the way for a more sustainable future. By reducing energy consumption by up to 30%, these systems are setting new benchmarks for environmental responsibility18.

In summary, generative systems are revolutionizing factory operations. Through innovation and collaboration, they are driving a transformation that enhances efficiency, quality, and sustainability.

Overcoming Implementation Challenges in AI Integration

Integrating advanced systems into traditional workflows presents unique challenges that require strategic solutions. Bridging legacy systems with modern technology is a critical step in this process. However, it often involves navigating risks, skills gaps, and data silos that can hinder progress19.

Bridging Legacy Systems with Modern Technology

One of the biggest hurdles is connecting outdated systems with new software. Legacy systems often lack the flexibility needed for seamless integration. This can lead to inefficiencies and increased costs20.

Practical solutions include using middleware to facilitate communication between old and new systems. This approach ensures data flows smoothly, reducing disruptions in production19.

Addressing Skills and Data Silos

Another challenge is the lack of skilled professionals who understand both legacy and modern systems. Training programs can bridge this gap, empowering teams to handle complex integration tasks21.

Data silos also pose a significant risk. By implementing unified data platforms, companies can ensure information is accessible and consistent across the organization. This enhances decision-making and improves overall efficiency19.

For example, companies like Ford have successfully tackled these challenges by leveraging synthetic data and advanced design tools21. Their approach highlights the importance of collaboration and innovation in overcoming integration hurdles.

To learn more about the challenges in system implementation, explore our detailed guide.

Enhancing Operational Efficiency and Workplace Safety with AI

Workplace safety and operational efficiency are now at the forefront of industrial advancements. The integration of intelligent solutions is transforming how factories approach both productivity and safety. By leveraging real-time monitoring and predictive analytics, businesses can ensure smoother operations while minimizing risks22.

Streamlined Processes and Proactive Maintenance

One of the key benefits of advanced systems is their ability to streamline processes. By automating repetitive tasks, factories can reduce errors and improve overall efficiency. For example, predictive maintenance can decrease equipment downtime by 50%, leading to significant cost savings23.

Proactive maintenance routines also enhance workplace safety. Real-time monitoring with sensors and cameras helps detect unsafe conditions, reducing the risk of accidents22. This approach ensures that workers can focus on complex tasks, boosting productivity and quality standards.

Another advantage is the improvement in supply chain management. Advanced systems monitor inventory levels and predict demand, reducing overproduction and shortages22. This optimization not only cuts costs but also ensures smoother operations across the board.

Companies that adopt these technologies report significant improvements in productivity and quality. For instance, defect rates can be reduced by up to 25%, enhancing overall product quality23. These advancements are setting new benchmarks for operational excellence in the industry.

In summary, the integration of advanced systems is reshaping how factories operate. By enhancing efficiency, safety, and maintenance, these technologies are driving a new era of innovation and productivity.

Future Trends and Opportunities in Digital Manufacturing

The next wave of innovation is reshaping how factories operate globally. Emerging tools and systems are driving a transformation that prioritizes efficiency, sustainability, and adaptability. These advancements are not just about improving processes; they are about redefining the future of production.

Emerging Technologies and Multi-Agent Systems

New technologies are at the heart of this evolution. Multi-agent systems, for example, enable factories to manage complex tasks with greater precision. These systems work collaboratively to optimize workflows, ensuring smoother operations and higher output quality24.

Companies like General Electric are leveraging advanced algorithms to reduce equipment downtime and enhance overall effectiveness24. This approach not only boosts productivity but also ensures consistent quality across the board.

Impact on Sustainability and Global Competitiveness

Sustainability is a key focus in modern production. By optimizing energy usage and reducing waste, factories can achieve significant cost savings while minimizing their environmental impact25. For instance, predictive maintenance powered by advanced systems can reduce downtime and maintenance costs, leading to more sustainable operations25.

Global competitiveness is also being redefined. Factories that adopt these technologies can respond faster to market demands, ensuring they stay ahead in a rapidly changing landscape24. This agility is critical for maintaining a strong position in the global market.

In summary, the future of production lies in the seamless integration of advanced systems. By focusing on sustainability, efficiency, and innovation, factories can unlock new opportunities and set new standards for the industry.

Conclusion

The integration of advanced systems is reshaping how manufacturers approach efficiency and innovation. By optimizing inventory levels and reducing costs, these systems enhance operational workflows. For instance, predictive maintenance has decreased machine downtime by 30%, ensuring smoother production26.

Robust management systems play a crucial role in this transformation. They enable real-time data analysis, improving decision-making and resource allocation. This approach not only boosts productivity but also ensures consistent quality across operations27.

Manufacturers leveraging these technologies gain a competitive edge. By adopting smarter systems, they can reduce waste, improve production efficiency, and create safer workplaces. This shift marks a new era of innovation and sustainability.

Looking ahead, the continuous evolution of advanced systems will drive further advancements. Manufacturers who embrace these changes will remain at the forefront of their industries, setting new standards for excellence.

FAQ

What is Industry 4.0 and how does it impact factories?

How do AI agents improve operational efficiency in manufacturing?

What role does predictive maintenance play in modern factories?

How does edge computing enhance manufacturing operations?

What are the benefits of integrating IoT in manufacturing?

How does AI contribute to supply chain optimization?

What challenges arise when implementing AI in manufacturing?

How does generative AI transform manufacturing processes?

Source Links

- The Role of Edge AI in Smart Factories and Industries 4.0

- What is Industry 4.0? Industry 4.0 Technology Guide | Plex

- What are Industry 4.0, the Fourth Industrial Revolution, and 4IR?

- Factory of the Future: How Industry 4.0 and AI Can Transform Manufacturing

- Industry 4.0 Smart Factory: Operations and Business Potential

- Artificial Intelligence: The Driving Force Of Industry 4.0 – Augury

- A Complete Guide to AI Agents in Manufacturing – Performix

- Empowering Industry 4.0 with AI and ML: Transforming Operations and Efficiency

- Edge AI in Smart Factories and Industries 4.0

- Where Agentic AI is Changing Manufacturing Operations

- How AI in Manufacturing Industry Controls Predictive Maintenance?

- AI in Manufacturing: Use Cases and Examples

- A Survey on AI-Driven Digital Twins in Industry 4.0: Smart Manufacturing and Advanced Robotics

- Smart manufacturing and the IoT are driving the Industry 4.0 revolution

- AI in inventory management: An overview

- AI Agents Revolutionizing Logistics Optimization in 2025

- How AI is Speeding the Rise of “Industry 4.0”

- Designing the Future of Intelligent Manufacturing with Generative AI

- The Data-Driven Path to AI in Manufacturing

- An Artificial Intelligence-Based Collaboration Approach in Industrial IoT Manufacturing: Key Concepts, Architectural Extensions and Potential Applications

- Artificial Intelligence Towards Future Industrial Opportunities and Challenges

- AI in Manufacturing: Enhancing Safety While Boosting Productivity

- AI Agents in Manufacturing 2025 Ultimate Guide

- AI in Manufacturing: Use Cases & Future Trends

- This is the future: Key Digital Manufacturing Trends Shaping 2025 | Plataine

- Industry 4.0: AI at the heart of the transformation

- Understanding Industrial AI Agents: A Deep Dive into the Future of Industry