The convergence of artificial intelligence and robotics has accelerated dramatically in recent years, creating a new generation of machines capable of performing increasingly complex tasks with minimal human intervention. As we move through 2025, AI-powered robots are no longer confined to research labs or science fiction—they’re actively reshaping industries, augmenting human capabilities, and transforming business operations across the global economy.

This technological revolution represents one of the most significant shifts in how we work since the dawn of the digital age. From manufacturing floors to hospital operating rooms, AI-powered robots are not just automating repetitive tasks but demonstrating unprecedented levels of adaptability, learning, and decision-making capabilities that were unimaginable just a few years ago.

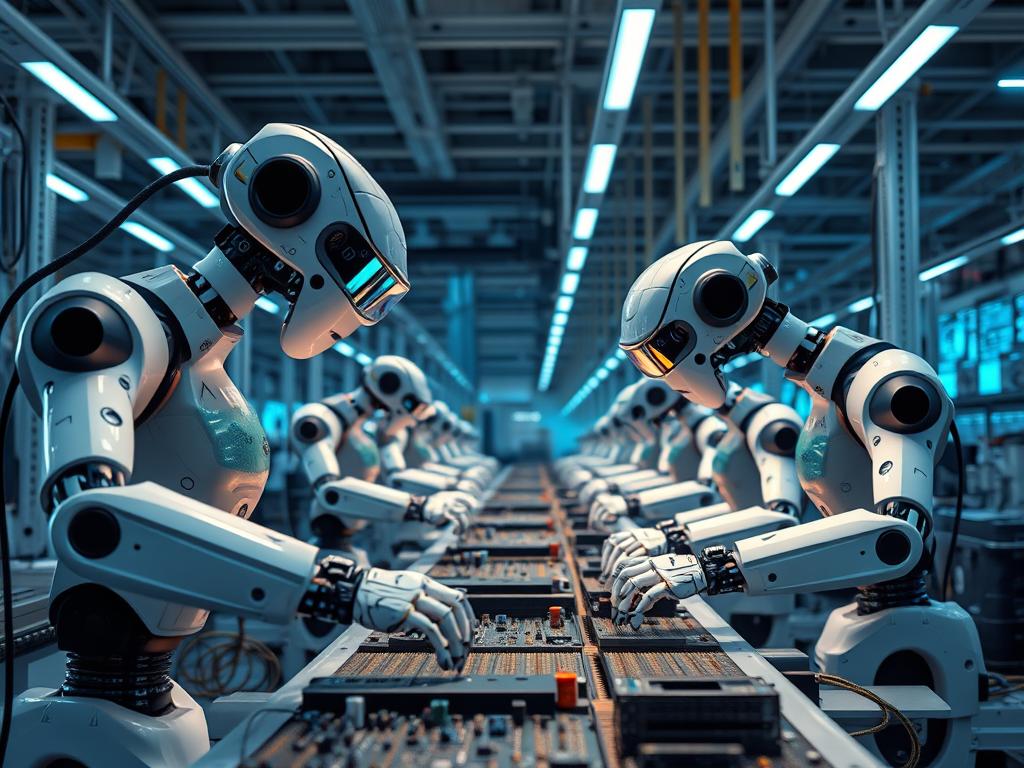

AI-powered robots working alongside humans in manufacturing environments represent one of the most visible applications of this technology in 2025.

Key Industries Transformed by AI-Powered Robots in 2025

The integration of AI with robotics has created machines that can not only execute programmed instructions but also learn from their environments, adapt to new situations, and make increasingly complex decisions. Here are the industries where AI-powered robots are making the most significant impact in 2025:

Manufacturing

Manufacturing has long been at the forefront of robotics adoption, but AI has transformed these machines from programmed tools to adaptive collaborators. Figure’s humanoid robots, backed by OpenAI, can now understand voice commands and manipulate objects they’ve never encountered before—a significant leap from traditional industrial robots.

Tesla’s Optimus robots are being deployed across their factories, with CEO Elon Musk targeting production of several thousand units in 2025. These robots can perform complex assembly tasks, quality control inspections, and even collaborate with human workers in mixed production environments.

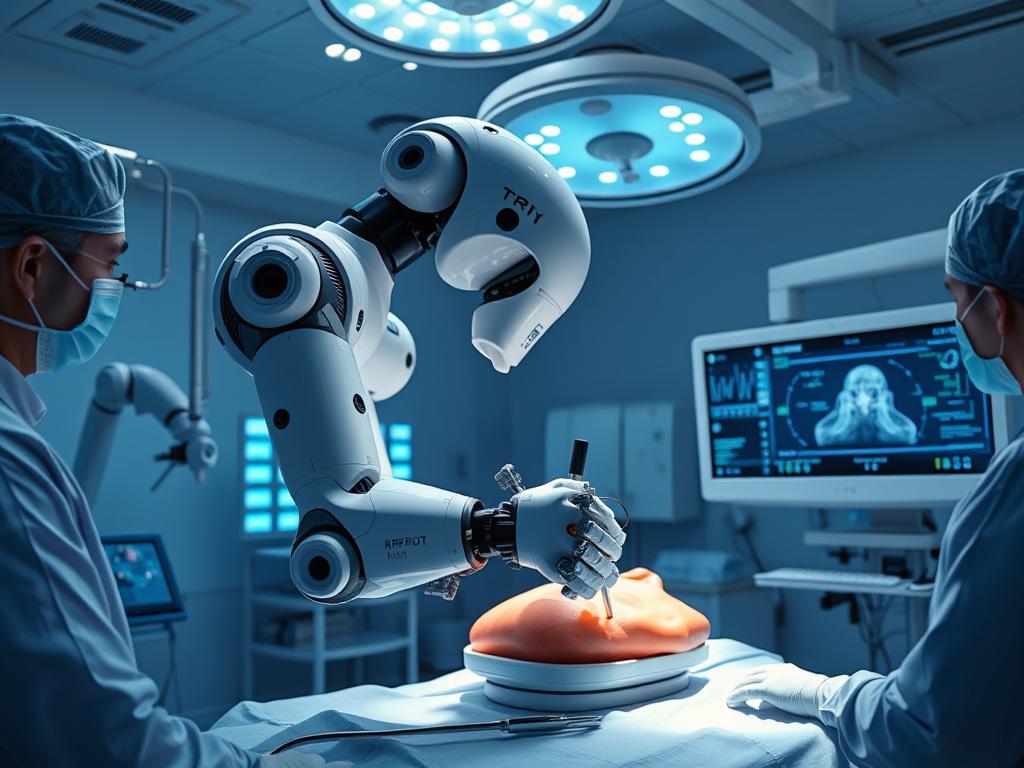

Healthcare

In healthcare, AI-powered robots are revolutionizing everything from surgery to patient care. Surgical robots enhanced with AI can now analyze real-time imaging data, patient records, and procedural best practices to assist surgeons with unprecedented precision and consistency.

AI diagnostic tools are outperforming human physicians in certain specialized tasks, particularly in radiology and pathology. Robots are also being deployed for patient monitoring, medication management, and even emotional support roles in elder care facilities, addressing critical staffing shortages in the healthcare sector.

Logistics and Warehousing

The logistics sector has embraced AI-powered robots to meet the ever-increasing demands of e-commerce and global supply chains. Autonomous mobile robots (AMRs) now navigate warehouse environments with remarkable efficiency, using computer vision and machine learning to identify, sort, and transport items without fixed infrastructure.

Companies like Amazon have expanded their robot fleet to include AI-powered picking robots that can identify and handle a vast array of products with different shapes, sizes, and fragility levels—a task that was considered too complex for automation just a few years ago.

Agriculture

Agriculture has seen a quiet revolution with AI-powered robots handling everything from planting and harvesting to crop monitoring and pest management. These agricultural robots can work around the clock in various weather conditions, using computer vision to identify ripe produce, detect diseases, and even perform selective weeding without chemicals.

The precision of these systems has led to significant reductions in water usage, pesticide application, and crop losses, while increasing yields and quality—addressing critical food security challenges in a changing climate.

Retail

In retail environments, AI-powered robots are transforming both the customer experience and back-end operations. Customer-facing robots now serve as interactive shopping assistants, providing product information, personalized recommendations, and even processing transactions in physical stores.

Behind the scenes, inventory management robots continuously monitor stock levels, identify misplaced items, and detect patterns that help retailers optimize their merchandising strategies. These systems integrate with supply chain data to ensure products are available when and where customers want them.

Construction

The construction industry has traditionally been slower to adopt automation, but AI-powered robots are now making significant inroads. Autonomous construction robots can perform dangerous or repetitive tasks like bricklaying, concrete pouring, and structural assembly with greater precision and safety than human workers.

These systems integrate with Building Information Modeling (BIM) data to ensure construction matches design specifications exactly, reducing errors and waste while accelerating project timelines in an industry that has struggled with productivity improvements.

Get the Complete Industry Analysis

Want to explore how AI-powered robots are transforming these industries in greater detail? Our comprehensive report includes adoption statistics, ROI analysis, and implementation strategies specific to your sector.

Real-World Case Studies: AI-Powered Robots in Action

Beyond the broad industry trends, examining specific implementations provides valuable insights into how organizations are successfully deploying AI-powered robots in 2025. Here are three detailed case studies that showcase the practical applications and measurable benefits:

Case Study 1: Amazon’s Next-Generation Fulfillment Centers

Amazon has been at the forefront of warehouse automation for years, but their 2025 fulfillment centers represent a quantum leap in capability. The company has deployed an integrated ecosystem of AI-powered robots that work in concert to process orders with minimal human intervention.

Implementation Details:

- Advanced picking robots that can identify and handle 99.7% of Amazon’s vast inventory without human assistance

- Coordinated fleet management AI that optimizes the movement of thousands of robots simultaneously

- Predictive inventory positioning that places products based on anticipated demand patterns

- Automated quality control systems that inspect packages before shipment

Measurable Results:

- 72% reduction in order processing time compared to 2022 facilities

- 94% decrease in picking errors, improving customer satisfaction

- Energy consumption reduced by 38% despite increased throughput

- Human workers shifted to supervision, programming, and customer service roles

Case Study 2: Mayo Clinic’s AI-Enhanced Surgical Suite

The Mayo Clinic has implemented a comprehensive AI-powered robotic surgical system that has transformed complex procedures, particularly in neurosurgery and cardiac interventions. This system represents the convergence of robotics, AI, imaging technology, and medical expertise.

Implementation Details:

- Multi-robot surgical environment where specialized machines handle different aspects of procedures

- Real-time integration of patient data, medical imaging, and procedural best practices

- AI systems that can predict complications before they occur and suggest preventive measures

- Haptic feedback systems that allow surgeons to “feel” tissues through robotic interfaces

Measurable Results:

- 43% reduction in surgical complications for complex procedures

- Average recovery time decreased by 37% compared to traditional surgical approaches

- Ability to perform procedures previously considered too risky

- Training time for new surgical techniques reduced by 61%

Case Study 3: John Deere’s Autonomous Farming Ecosystem

John Deere has revolutionized agriculture with their integrated ecosystem of AI-powered autonomous farming equipment. This system allows a single farmer to manage operations across thousands of acres with unprecedented precision and efficiency.

Implementation Details:

- Fleet of autonomous tractors, harvesters, and specialized robots that can operate 24/7

- AI-driven crop management system that makes decisions at the individual plant level

- Integrated soil sensors, weather data, and satellite imagery for optimized resource application

- Predictive maintenance systems that prevent equipment failures before they occur

Measurable Results:

- Crop yields increased by 32% while reducing water usage by 47%

- Fertilizer and pesticide application reduced by 59% through precision targeting

- Labor requirements decreased by 78% for routine farming operations

- Carbon footprint of farming operations reduced by 41% compared to traditional methods

Challenges and Considerations in AI-Powered Robotics Adoption

Despite the impressive capabilities and benefits of AI-powered robots in 2025, organizations implementing these technologies face significant challenges that must be carefully addressed:

Technical Challenges

- Integration Complexity: Connecting AI-powered robots with existing systems and infrastructure often requires substantial redesign of operational processes.

- Data Security: As Lieberman from Kusari notes, “AI will become more widespread and challenging to detect,” with increasing concerns about malicious models and data poisoning attacks.

- Reliability and Safety: Ensuring consistent performance in unpredictable real-world environments remains challenging, particularly for robots operating alongside humans.

- Maintenance Requirements: Advanced robots require specialized maintenance skills and parts that may not be readily available in all locations.

Workforce and Ethical Considerations

- Job Displacement: Oxford Economics predicted that “20 million manufacturing jobs could be displaced by 2030,” requiring significant workforce transitions.

- Skill Gaps: Organizations struggle to find workers with the expertise to program, maintain, and collaborate effectively with AI-powered robots.

- Ethical Decision-Making: As robots make more autonomous decisions, questions about accountability and ethical frameworks become increasingly important.

- Privacy Concerns: Robots that continuously monitor environments raise questions about data collection and usage, particularly in sensitive settings.

The “digital divide” in robotics adoption creates significant disparities between regions and industries with access to these technologies and those without.

“The societal challenge we highlighted in 2019 has also intensified. The digital divide has widened. Advanced economies with capital to invest in AI and robots are poised to reap the benefits, while developing nations reliant on low-cost labor may struggle to compete.”

Future Outlook: AI-Powered Robotics Beyond 2025

The rapid evolution of AI-powered robots shows no signs of slowing. Looking beyond 2025, several key trends are likely to shape the next generation of these technologies:

Enhanced Human-Robot Collaboration

Future AI-powered robots will feature significantly improved capabilities for natural interaction with humans. Advances in natural language processing, emotion recognition, and contextual understanding will enable more intuitive collaboration between humans and machines.

These developments will expand the range of tasks that can be effectively shared between humans and robots, creating truly collaborative workplaces where each contributes their unique strengths.

Self-Evolving Systems

The next frontier in AI-powered robotics involves systems that can autonomously improve their own designs and capabilities. These self-evolving robots will use advanced reinforcement learning to optimize their physical configurations and operational parameters for specific tasks.

This capability will dramatically accelerate the development cycle for specialized robots, allowing them to adapt to new challenges without explicit human programming or redesign.

Swarm Intelligence

Swarm robotics—where large numbers of relatively simple robots work together as a coordinated system—will become increasingly sophisticated. These systems will demonstrate emergent intelligence that exceeds the capabilities of individual units.

Applications will range from microscale medical interventions to large-scale construction and disaster response, where adaptability, redundancy, and collective problem-solving provide significant advantages over traditional approaches.

Expert Insight: “By 2030, we expect to see AI-powered robots that can not only perform physical tasks but also engage in complex decision-making processes that were previously thought to require human judgment. The distinction between human and machine capabilities will continue to blur, creating both unprecedented opportunities and profound challenges for society.” — Dr. Alejandro Rivas-Vasquez, Global Head of Digital Forensics and Incident Response at NCC Group

Conclusion: Navigating the AI-Powered Robotics Revolution

The integration of AI and robotics has reached a critical inflection point in 2025, with practical applications now extending across virtually every sector of the economy. These technologies are no longer experimental or limited to controlled environments—they are actively reshaping how we work, produce goods, deliver services, and interact with machines.

For organizations looking to remain competitive, understanding where and how AI-powered robots are already working provides essential context for strategic planning and implementation. The examples and case studies highlighted in this article demonstrate that successful adoption requires not just technological investment but also thoughtful consideration of integration challenges, workforce impacts, and ethical implications.

As we look beyond 2025, the continued evolution of these technologies promises even greater capabilities and applications. Organizations that develop the expertise to effectively implement and manage AI-powered robotics today will be well-positioned to leverage these future advancements, creating sustainable competitive advantages in an increasingly automated world.